Applications

INDUSTRIES: Aerospace

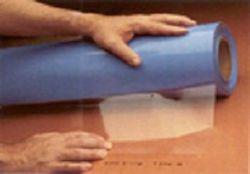

APPLICATION: Surface Protection

APPLICATION DESCRIPTION:

Surface protection of metals. Especially well suited for polished aluminum. Performs well during stretch forming, drilling, routing and shearing operations. Protects through heat aging and degreasing through clean line or alodining process. Allows maximum abrasion resistance during in-house processing, storage and transportation. Used on aircraft skins in metal fabricating operations. PROTEX 8216-2 can remain on various metals during such operations as vapor degreasing and solvent cleaning with MEK, Trichloroethylene, Toluene, De-natured Alcohol and IPA, with no adverse effect to polyester film or adhesive.

The chemical and heat resistance of the polyester film is one of the reasons why it is chosen over some other films available. The adhesive was designed to withstand the pressure and heat (Typical: 2 hours at 350°F. and 72 hours at 275°F., and autoclave pressure and heat, 2 hours at 350°F. with 35 PSI) with no residue or transfer of adhesive.

APPLICATION NOTES:

Application surface: Metals, Plastics, Glass, Painted Surfaces

Technical Data

Mask-Off Protex 8216-2

MATERIAL DESCRIPTION:

| ADHESIVE TYPE: | Pressure-Sensitive |

| CONSTRUCTION: | Single Coated |

TECHNICAL DATA:

| ADHESIVE LAYER: | Acrylic |

| ADHESIVE LAYER DESCRIPTION: | Acrylic Latex |

| BACKING/CARRIER MATERIAL: | Film |

| THICKNESS: | 2 mil |

| ADHESION TO STEEL: | oz/inch width 1-3 (-.2/+.6) (At time of manufacture) PSTC-1 (Modified) |

| TENSILE STRENGTH: | PSI/mil 30,000 |

| ELONGATION: | % M.D. 106 min |

| TEMPERATURE OPERATING: | 150° for 1 hour, 300° for 1 hour, 350° for 2 hours, No heat |

Protex 8216-2 Tech Data Sheet