800PEEL STRENGTH PSTC-1 (ASTM D 3330):

15 Min 54.4 oz/inch average

3 Day 129.6 oz/inch average

30 Day 152.3 oz/inch average

TENSILE STRENGTH PSTC-31

ENGLIGH METRIC

23.6 lbs. / 1" width average 105.02N / 25mm average

WEIGHT: 4.5 +/- .3oz/square yard

FLAMMABILITY 12 SECOND VERTICAL BURN:

FLAMMABILITY 12 SECOND VERTICAL BURN:

Burn Length 3.4 inches maximum

Flame Time 0 Seconds

Drip Flame Time No Drips

Flame Time 0 Seconds

Drip Flame Time No Drips

SHELF LIFE: Minimum of 12 months in cool, dry storage

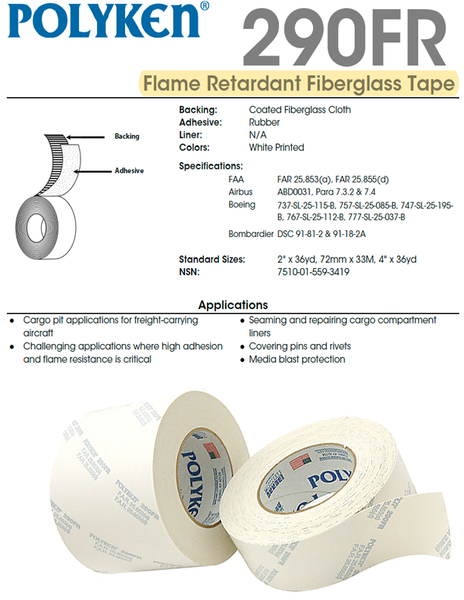

PASSES SPECIFICATIONS:

DMS-1984 Rev. P Type 6 Class 2

FAA Radiant heat Panel FAR 25.856 (A)

FAR PART 25.853 (A,B)

DMS-1511 12 second vertical burn

BSS-7230 12 second vertical burn

770-3FRD Tech Data Sheet